Top Hardware Components for Building a Durable Deck

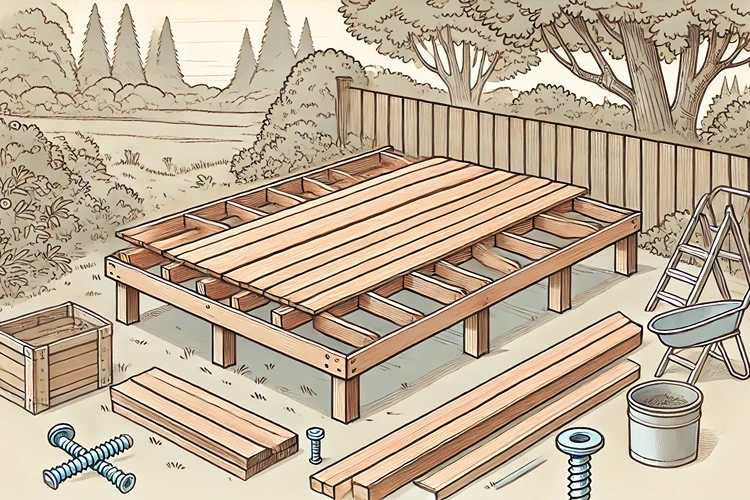

Building a deck is an exciting project that can significantly enhance your outdoor living space. But to ensure your deck stands the test of time, you need to focus on selecting the right hardware components. Whether you’re a seasoned builder or a DIY enthusiast, understanding which materials and tools to use is crucial for creating a deck that’s not only beautiful but also durable. In this article, we’ll dive into the top hardware components you need to consider when building a long-lasting deck.

Why Choosing the Right Hardware Matters

When it comes to deck building, the hardware you choose is just as important as the wood or composite material. The hardware serves as the backbone of your deck, holding everything together and ensuring stability over time. Poor-quality hardware can lead to a host of problems, including rust, structural weaknesses, and even safety hazards. So, what exactly should you be looking for when selecting hardware components for your deck?

What Are the Essential Hardware Components?

Before you start building, it’s important to familiarize yourself with the essential hardware components. These include fasteners, connectors, joist hangers, bolts, and more. Each of these plays a specific role in the overall construction and durability of your deck. Let’s explore each component in detail to understand its importance.

Fasteners: The Backbone of Your Deck

Fasteners are arguably the most crucial component when it comes to deck construction. They’re responsible for securing the deck boards to the underlying structure, ensuring that everything stays in place. There are several types of fasteners to choose from, including screws, nails, and hidden fasteners.

Deck Screws

Deck screws are the go-to option for most builders due to their superior holding power. Unlike nails, screws are less likely to loosen over time, making them ideal for securing deck boards. They come in various lengths and materials, but stainless steel screws are highly recommended for their resistance to corrosion.

Helpful Hint:

When selecting deck screws, opt for those specifically designed for outdoor use. Look for screws with corrosion-resistant coatings to prevent rust and extend the life of your deck.

Nails vs. Screws: Which Is Better?

While nails are quicker to install, screws offer better long-term durability. Nails can loosen over time, leading to a less stable deck. For this reason, many experts recommend using screws for deck construction, especially in areas that experience fluctuating weather conditions.

Joist Hangers: Ensuring Structural Integrity

Joist hangers are metal brackets that are used to secure the joists to the ledger board, providing critical support for the entire deck. They help distribute the weight evenly, preventing the deck from sagging or collapsing. When choosing joist hangers, it’s essential to select those made from galvanized steel or stainless steel to avoid rust and corrosion.

Why Galvanized Steel is a Must

Galvanized steel joist hangers are treated with a protective coating that prevents rust, making them ideal for outdoor structures like decks. This coating significantly extends the life of the hardware, ensuring that your deck remains sturdy for years to come.

Stats:

According to a study by the National Association of Home Builders, decks built with galvanized steel joist hangers are 30% more durable than those using untreated metal hangers.

Proper Installation Tips

When installing joist hangers, it’s crucial to use the right nails or screws. Make sure the fasteners are compatible with the hangers and that they’re driven in securely to avoid any wobbling or instability. Double-check the alignment to ensure everything is level before proceeding with the rest of the deck construction.

Post Anchors: Securing Your Deck Foundation

Post anchors are vital for securing the deck posts to the ground, providing a stable foundation for the entire structure. They come in various types, including surface-mounted and embedded anchors. The choice between them depends on your specific deck design and the ground conditions.

Surface-Mounted vs. Embedded Anchors

Surface-mounted anchors are easier to install and are often used when the deck is being built on an existing concrete slab. Embedded anchors, on the other hand, offer greater stability as they are set into the concrete during the foundation pouring process. For decks that are raised or built on uneven terrain, embedded anchors are usually the better option.

Properly installing post anchors is key to ensuring your deck remains stable over time. Make sure to follow the manufacturer’s instructions carefully and use the recommended hardware for the best results.

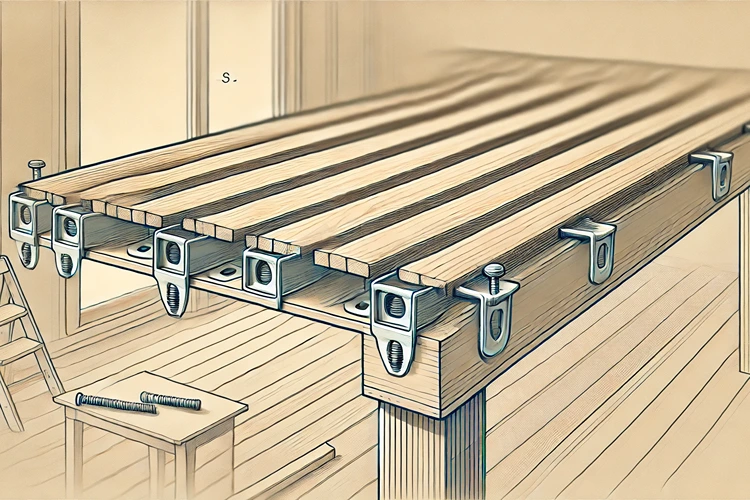

Deck Board Connectors: The Hidden Support

Deck board connectors are used to secure the deck boards to the joists without visible fasteners, creating a clean and polished look. These connectors are especially popular for composite and PVC decking, where a seamless appearance is often desired.

Benefits of Hidden Fasteners

Hidden fasteners not only enhance the visual appeal of your deck but also reduce the risk of splinters and stubbed toes. They help maintain the integrity of the deck surface by minimizing the number of exposed screws and nails. Additionally, hidden fasteners allow the deck boards to expand and contract with temperature changes, reducing the likelihood of cracks and splits.

Helpful Hint:

When using hidden fasteners, be sure to choose ones that are compatible with the type of decking material you’re using. This ensures a secure fit and long-lasting durability.

Choosing the Right Material for Deck Hardware

The material of your deck hardware can make or break the longevity of your deck. From stainless steel to galvanized steel and even plastic, each material has its pros and cons. Let’s take a closer look at the most common materials and how they impact the durability of your deck.

Stainless Steel: The Gold Standard

Stainless steel is widely regarded as the best material for deck hardware due to its exceptional resistance to rust and corrosion. It’s particularly beneficial in coastal areas where saltwater exposure can quickly deteriorate other metals. While stainless steel hardware is more expensive than other options, the investment pays off in the long run through reduced maintenance and increased longevity.

When to Use Stainless Steel

Stainless steel hardware is ideal for high-moisture environments or areas that experience extreme weather conditions. If your deck is near a pool, hot tub, or the ocean, stainless steel is the best choice to prevent rust and maintain structural integrity over time.

Galvanized Steel: A Cost-Effective Alternative

Galvanized steel offers a more affordable option without compromising too much on durability. The galvanization process involves coating the steel with a layer of zinc to protect it from rust. While not as resistant as stainless steel, galvanized steel is still a solid choice for most deck-building projects, especially if you’re working within a budget.

Understanding the Limits of Galvanized Steel

While galvanized steel is more resistant to corrosion than untreated steel, it’s not completely immune. Over time, the zinc coating can wear off, especially in harsh environments. Regular maintenance, such as inspecting and replacing worn hardware, can help extend the life of galvanized steel components.

Stats:

A report from the American Galvanizers Association found that galvanized steel hardware can last up to 70 years in mild environments but may require replacement after 10-15 years in coastal or industrial areas.

Plastic and Composite Hardware: A Modern Option

Plastic and composite materials are becoming increasingly popular in deck construction, especially for hidden fasteners and connectors. These materials are resistant to rust, corrosion, and UV damage, making them an attractive option for long-lasting deck hardware. However, they may not offer the same strength as metal components, so it’s important to use them appropriately.

Where Plastic and Composite Shine

Plastic and composite hardware are ideal for low-stress areas of the deck where appearance and weather resistance are key. They’re often used in conjunction with metal hardware to provide a balance of aesthetics and strength. For example, you might use plastic hidden fasteners to secure the deck boards while relying on stainless steel for the joist hangers and post anchors.

Additional Hardware Components for a Durable Deck

Beyond the basics of fasteners, joist hangers, and post anchors, there are other critical hardware components that contribute to the overall durability of your deck. Let’s take a closer look at these components and how they play a role in maintaining a long-lasting outdoor space.

Ledger Board Fasteners: A Crucial Connection

The ledger board is the piece of lumber that attaches your deck to your house, and it’s one of the most important structural elements. Without a secure connection, your deck could pull away from the house over time, leading to potential collapse. Ledger board fasteners, such as lag screws or bolts, are used to secure the ledger board firmly to the house, ensuring stability and safety.

Lag Screws vs. Bolts: Which Is Best?

Lag screws and bolts are the most common options for securing ledger boards. Lag screws are easier to install, as they don’t require access to both sides of the ledger board, but bolts provide a stronger connection. When using bolts, it’s important to include washers to distribute the load and prevent the wood from splitting.

Helpful Hint:

Always use washers with lag screws or bolts when securing the ledger board. This helps distribute the pressure more evenly and prevents the fastener from pulling through the wood.

Flashing: Protecting Your Deck from Water Damage

Flashing is a thin layer of material installed where the deck meets the house to prevent water from seeping into the structure. This is crucial for preventing water damage, which can lead to rot and deterioration of both the deck and the house. Flashing is typically made of metal, such as aluminum or copper, but can also be made from plastic or rubber.

Installing Flashing Correctly

Proper installation of flashing is key to its effectiveness. The flashing should be installed under the siding of your house and over the ledger board to create a watertight seal. It’s important to ensure that the flashing extends past the edge of the deck to direct water away from the house.

Neglecting to install or properly seal flashing can lead to significant structural damage over time, so it’s worth taking the extra time to do this step correctly.

Corner Braces: Reinforcing the Deck Frame

Corner braces, also known as angle brackets, are used to reinforce the corners of your deck frame. These metal brackets provide additional support and help prevent the frame from twisting or shifting over time. While they might not be necessary for every deck, they’re a good addition if you’re building a larger or more complex structure.

When to Use Corner Braces

Corner braces are especially useful for decks built in areas prone to high winds or seismic activity. They provide extra stability and peace of mind, ensuring that your deck remains secure even in challenging conditions. If you’re building a multi-level deck or one with unusual angles, corner braces can also help maintain structural integrity.

Deck Hardware Guide: Material Recommendations

| Hardware Type | Best Material | Ideal Application |

|---|---|---|

| Deck Screws | Stainless Steel | High-moisture areas, near pools or coastlines |

| Joist Hangers | Galvanized Steel | General deck construction, non-coastal regions |

| Post Anchors | Galvanized Steel | Raised decks or uneven terrain |

| Hidden Fasteners | Plastic/Composite | Composite or PVC decking for a seamless look |

| Ledger Board Fasteners | Bolts with Washers | Securing the deck to the house for maximum stability |

Best Practices for Installing Deck Hardware

Even the highest-quality hardware won’t do much good if it’s not installed properly. Following best practices during installation can make a significant difference in the longevity and durability of your deck. Here are some tips to keep in mind as you work on your project.

Pre-Drill Holes to Prevent Splitting

When installing screws or bolts, it’s a good idea to pre-drill holes in the wood. This reduces the risk of splitting, especially when working with hardwoods or pressure-treated lumber. Pre-drilling also makes it easier to drive the fasteners in, ensuring a more secure fit.

Choosing the Right Drill Bit Size

The size of the drill bit you use should match the diameter of the screw shank (not the threads). This ensures that the screw grips the wood effectively without causing unnecessary stress that could lead to splitting.

Use a Torque Wrench for Consistent Tightening

When installing bolts, using a torque wrench ensures that each fastener is tightened to the same degree, preventing uneven pressure that could weaken the structure. Over-tightening can crush the wood fibers, while under-tightening can leave the connection loose. A torque wrench allows you to apply just the right amount of force for a secure and durable connection.

Why Consistency Matters

Consistent tightening is key to maintaining the structural integrity of your deck. Uneven pressure can lead to stress points, making the deck more susceptible to damage over time. By using a torque wrench, you can avoid these issues and ensure a longer lifespan for your deck.

Stats:

A study by the Wood Products Council found that decks constructed with consistent fastener torque had a 25% lower failure rate compared to those with inconsistently tightened fasteners.

Inspect Hardware Regularly

Over time, even the best hardware can wear out or become loose. Regular inspections are essential to catching potential issues early and preventing them from turning into major problems. Make it a habit to inspect your deck’s hardware at least once a year, paying close attention to fasteners, connectors, and any signs of rust or corrosion.

What to Look For During Inspections

During your inspections, check for loose screws or bolts, signs of rust or corrosion, and any warped or damaged wood. Replace any compromised hardware immediately to maintain the safety and stability of your deck. It’s also a good idea to re-tighten screws and bolts as needed to keep everything secure.

Maintaining Your Deck for Longevity

Building a durable deck is just the first step. Proper maintenance is key to ensuring that your deck remains safe and beautiful for years to come. Here are some maintenance tips that can help you get the most out of your deck hardware.

Keep Your Deck Clean

Dirt, leaves, and debris can accumulate on your deck over time, leading to moisture buildup and potentially damaging the hardware. Regularly cleaning your deck helps prevent these issues, extending the life of your deck and its hardware.

Best Practices for Cleaning

Use a broom or leaf blower to remove loose debris, and clean the deck surface with a mild detergent and water. Avoid using harsh chemicals that can damage the wood or metal components. For stubborn stains, a pressure washer can be effective, but use it cautiously to avoid damaging the deck surface.

Protect Your Deck from Moisture

Moisture is one of the biggest threats to your deck’s longevity, particularly if you live in a wet or humid climate. Protecting your deck from moisture can significantly extend its life and keep the hardware in good condition.

Applying Sealants and Stains

Applying a waterproof sealant or stain helps protect the wood from moisture, reducing the risk of rot and warping. Choose a product that’s specifically designed for decks and apply it according to the manufacturer’s instructions. Reapply the sealant or stain every few years, or as recommended, to maintain the protective barrier.

Replace Worn or Damaged Hardware

Over time, some hardware components may wear out or become damaged. It’s important to replace these components promptly to prevent further issues. Keeping spare hardware on hand can make it easier to make quick repairs as needed.

Where to Get Replacement Hardware

When replacing hardware, make sure to use the same type and size as the original components. This ensures compatibility and maintains the structural integrity of your deck. You can find replacement hardware at most home improvement stores or online, but always opt for high-quality materials to match the durability of your original build.

Choosing the Best Hardware Suppliers

To build a deck that stands the test of time, it’s essential to source your hardware from reputable suppliers. The quality of the materials you use directly impacts the durability and safety of your deck. Here’s how to choose the best suppliers for your deck hardware needs.

Research Supplier Reputation

Start by researching potential suppliers to ensure they have a solid reputation in the industry. Look for suppliers that specialize in outdoor and decking hardware, as they are more likely to offer products designed to withstand the elements. Customer reviews and ratings can also provide valuable insights into the reliability and quality of a supplier’s products.

What to Look for in Reviews

Pay attention to customer feedback regarding the durability of the hardware, customer service, and delivery times. A supplier with consistently positive reviews is more likely to provide high-quality products and reliable service. Don’t hesitate to reach out to the supplier directly if you have any specific questions or concerns about their products.

Compare Prices Without Compromising Quality

While it’s important to stay within your budget, choosing the cheapest option isn’t always the best approach. Lower prices can sometimes indicate lower quality, which could lead to costly repairs or replacements down the line. Instead, aim to find a balance between price and quality.

Getting the Best Value for Your Money

Compare prices from several suppliers to get a sense of the market rate for the hardware you need. Look for any warranties or guarantees that suppliers offer, as these can provide added peace of mind. In some cases, investing a bit more upfront can save you money in the long run by reducing maintenance costs and extending the life of your deck.

Consider Local vs. Online Suppliers

Deciding whether to purchase from a local supplier or an online retailer depends on your specific needs and preferences. Local suppliers offer the advantage of seeing the products in person before purchasing, while online retailers often provide a wider selection and competitive prices.

Benefits of Local Suppliers

Buying from a local supplier allows you to inspect the materials firsthand, ensuring they meet your quality standards. Additionally, local suppliers can offer personalized advice and recommendations based on your specific project and regional climate conditions. Supporting local businesses also contributes to your community’s economy.

Advantages of Online Shopping

Online suppliers often have a more extensive inventory, allowing you to find specialized hardware that might not be available locally. Many online retailers also offer customer reviews, which can help you make informed decisions. Just be sure to check shipping costs and return policies before making a purchase.

Key Takeaways for Building a Durable Deck

Building a durable deck requires careful planning, the right materials, and attention to detail during construction. By focusing on high-quality hardware, proper installation techniques, and regular maintenance, you can ensure that your deck remains safe and beautiful for years to come. Here’s a summary of the key points to remember:

- Choose high-quality fasteners, joist hangers, post anchors, and other essential hardware to ensure the structural integrity of your deck.

- Consider using stainless steel or galvanized steel for hardware components to prevent rust and corrosion.

- Proper installation techniques, such as pre-drilling holes and using a torque wrench, can prevent issues like splitting and uneven tightening.

- Regularly inspect and maintain your deck to catch potential issues early and extend the life of your hardware.

- Research and choose reputable hardware suppliers, balancing cost with quality to get the best value for your investment.

Pros and Cons of Different Deck Hardware Materials

Pros

- Stainless steel is highly resistant to rust and corrosion, making it ideal for coastal areas.

- Galvanized steel is cost-effective and offers decent resistance to corrosion in non-coastal environments.

- Plastic and composite hardware are resistant to UV damage and are excellent for hidden fasteners.

- Using the right material for your specific climate can extend the life of your deck hardware.

Cons

- Stainless steel can be expensive, increasing the overall cost of the project.

- Galvanized steel may require replacement sooner in harsh environments.

- Plastic and composite hardware may not provide the same strength as metal components.

- Choosing the wrong material for your environment can lead to premature hardware failure.

FAQs

Wrapping Up

Building a durable deck involves more than just selecting attractive materials; it requires careful consideration of the hardware components that will keep your deck secure and stable for years to come. By choosing high-quality fasteners, joist hangers, and post anchors, and following best practices for installation and maintenance, you can ensure that your deck remains a safe and inviting space for your family and friends.

Remember to consider the specific conditions of your environment when selecting hardware, and don’t hesitate to invest in materials that offer the best balance of durability and cost-effectiveness. Regular inspections and maintenance are key to prolonging the life of your deck, so make them part of your routine.

With the right approach, your deck can become a lasting feature of your home, providing a space for relaxation, entertainment, and memories for years to come. Whether you’re a DIY enthusiast or working with a contractor, understanding the importance of quality hardware is essential to building a deck that truly stands the test of time.